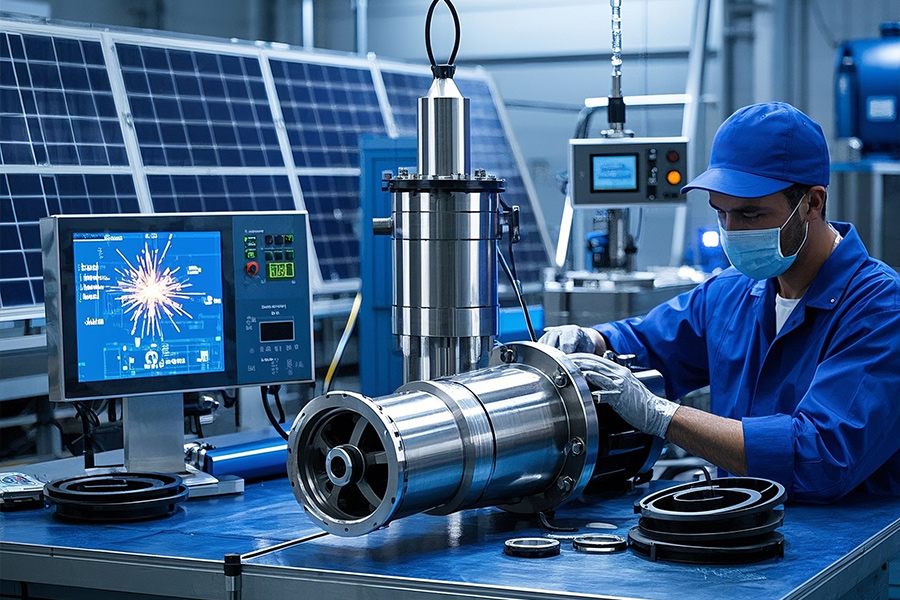

QD Multi-Stage Submersible Pump for Demanding Industrial Applications

The Multi-Stage Submersible Pump is an advanced solution engineered to...

In the world of water handling and fluid transfer, selecting the right pump is essential to ensure efficiency, durability, and reliable operation. Each serves specific purposes and offers unique structural and functional features. So, how do these pumps differ, and where is each one typically used?

What Is a Large-Scale Water Pump Unit Used For?

A Large-Scale Water Pump Unit is designed to handle significant volumes of water over long distances or within heavy-duty industrial systems. These units are often installed in water supply stations, municipal flood control projects, irrigation systems, and power plants.

Unlike standard pumps, a Large-Scale Water Pump Unit combines large-capacity pump heads with motors, control systems, and reinforced piping. The setup is usually installed permanently or semi-permanently, depending on the project needs. These pump units are capable of transporting thousands of cubic meters of water daily, making them suitable for infrastructure-level operations.

Due to the scale of operation, these units often require special attention to installation conditions, maintenance schedules, and system monitoring. A well-designed Large-Scale Water Pump Unit helps maintain stable water pressure, supports consistent output, and performs under continuous operation in demanding environments.

What Makes a High-End Water Pump Different?

A High-End Water Pump focuses on quality construction, precise engineering, and advanced control features. While it may not handle volumes as large as industrial units, it is valued in systems where consistency, durability, and efficient flow control are required.

Common uses of a High-End Water Pump include commercial building water supply, HVAC systems, fire-fighting booster stations, and factory production lines. These pumps often feature variable speed control, corrosion-resistant materials, and low-vibration operation, allowing them to perform steadily in both residential and industrial settings.

One benefit of a High-End Water Pump is its ability to maintain reliable output while using less energy and requiring less frequent maintenance. In systems that need exact pressure or temperature regulation, these pumps provide a dependable solution. They are often selected for long-term use in technical systems where pump failure could result in operational delays or safety concerns.

Where Are Submersible Electric Pumps Effective?

A Submersible Electric Pump is built for use while fully submerged in water or other fluids. It combines a sealed electric motor with an impeller unit to lift water efficiently from wells, sumps, tanks, or flooded areas. These pumps are especially useful in areas where surface installation is difficult or space is limited.

The Submersible Electric Pump is commonly found in residential drainage, construction site dewatering, wastewater treatment, and rural water extraction. Because it operates underwater, it avoids issues like air lock or suction loss that can occur with above-ground pumps.

Another benefit of the Submersible Electric Pump is its quiet and compact design. With no exposed moving parts and minimal surface space requirements, it fits easily into narrow or deep spaces. Many models are equipped with float switches for automatic start and stop, allowing for hands-free operation in changing water levels.

How to Choose Between These Pump Types?

Choosing between a Large-Scale Water Pump Unit, a High-End Water Pump, and a Submersible Electric Pump depends on several factors: the volume of water to be handled, installation location, control requirements, and project scope.

For municipal or agricultural systems requiring high volume and long-distance transfer, a Large-Scale Water Pump Unit is appropriate. In contrast, buildings or manufacturing systems that demand consistent and quiet operation may benefit more from a High-End Water Pump. For temporary or submerged applications, the Submersible Electric Pump offers a practical and space-saving solution.

Understanding the strengths and limits of each type ensures better system performance and long-term reliability across various industries and projects.